Call us

+86-19818583496

+86-0577-68586867

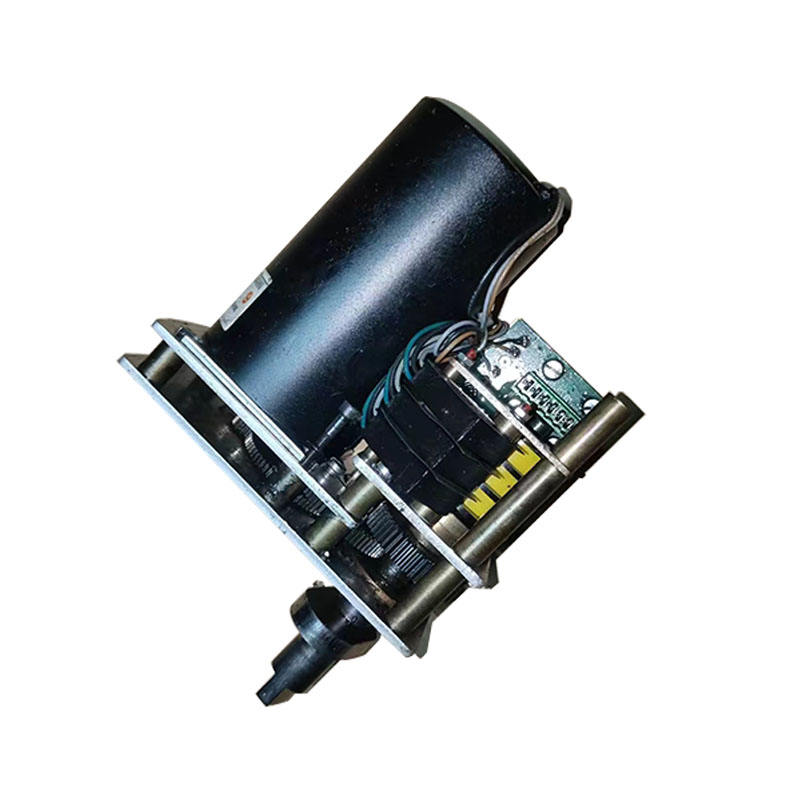

Printing machine motors are essential components in modern printing machines, influencing machine performance, output stability, and material handling. From web-fed presses to digital systems, the choice of motor affects factors such as registration, web tension, and print head movement. Common motor types used in industrial printing include servo motors, brushless DC motors, and specialized linear and torque motors.

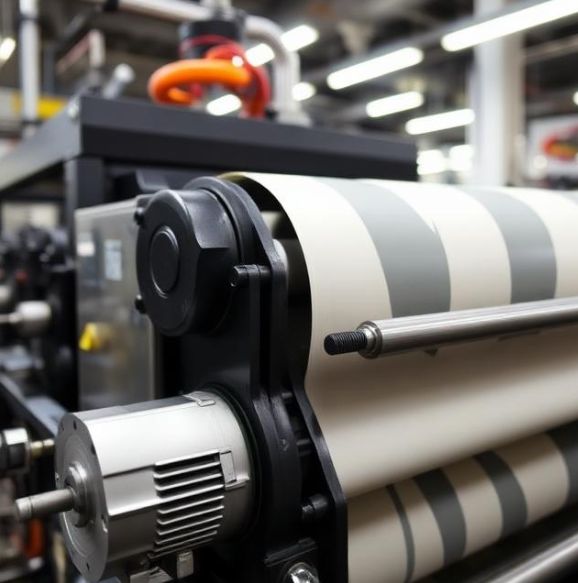

One main application for motors in printing machines is print head positioning and media handling. In multi-pass printing, small changes in motor movement can affect the alignment of ink on the media. Servo motors allow control of the print head movement and help maintain consistent placement of ink droplets. These motors also support web tension management in roll-to-roll printing, adjusting the speed of rollers to maintain even feeding and reduce distortion of the material.

Another important function is color registration control. Many printing processes use multiple color plates, and alignment between these plates determines how the final image appears. Motors with feedback systems assist in controlling the movement of rollers and print heads, which supports alignment between passes and contributes to uniform output throughout the run.

The printing motor market includes a wide variety of motor types designed for industrial printing equipment. Stepper motors, AC and DC motors, and servo motors are used depending on the requirements of the machine. Servo motors are often applied in processes requiring controlled movement of the media or print heads, while stepper motors are common in applications where movement can be programmed in steps. Brushless DC motors are valued for their ability to operate with reduced energy consumption and lower maintenance needs.

Linear and torque motors are also part of some printing machines. Linear motors can drive components directly, reducing the number of mechanical parts and simplifying movement. Torque motors provide controlled rotational force, which is useful for machines that require slow, steady motion for rollers, tables, or indexing mechanisms. These motor types are selected based on the motion requirements of the printing system.

Manufacturers of printing machines consider factors such as energy use, operational stability, and the reliability of motion systems when selecting motors. Supply availability and initial costs are also taken into account. Combining motor technologies with automated machine systems can improve control of media movement, support consistent production results, and allow integration with digital monitoring or maintenance tools.

Printing machine motors play roles in a variety of printing applications, including flexible packaging, commercial printing, and industrial labeling. Their function affects the quality of output, the efficiency of production, and the ability to manage different materials and ink types. As manufacturing systems evolve, the integration of motor control with machine automation remains a key part of printing machine design.

Frequently Asked Questions

Q1: What factors should be considered when selecting a printing machine motor?

A1: Factors include the type of printing process, the speed of operation, load requirements, energy use, and compatibility with the machine’s control system.

Q2: How does motor maintenance impact printing operations?

A2: Regular maintenance, such as checking connections, lubricating components, and monitoring performance, can help reduce interruptions and extend the motor’s operational life.

Q3: Are there differences in motor choice for digital versus analog printing machines?

A3: Yes, digital machines often use motors with responsive control for moving print heads and substrates, while analog systems may prioritize motors for rollers, plates, or feeding mechanisms.

Q4: How do environmental factors affect printing machine motors?

A4: Temperature, humidity, dust, and vibration can influence motor performance. Proper installation, cooling, and protection measures help maintain consistent operation.

Q5: What types of sensors are commonly used with printing motors?

A5: Sensors such as encoders, tachometers, and load monitors are used to track speed, position, and torque, supporting motion control and operational stability.

Contact Us