Call us

+86-19818583496

+86-0577-68586867

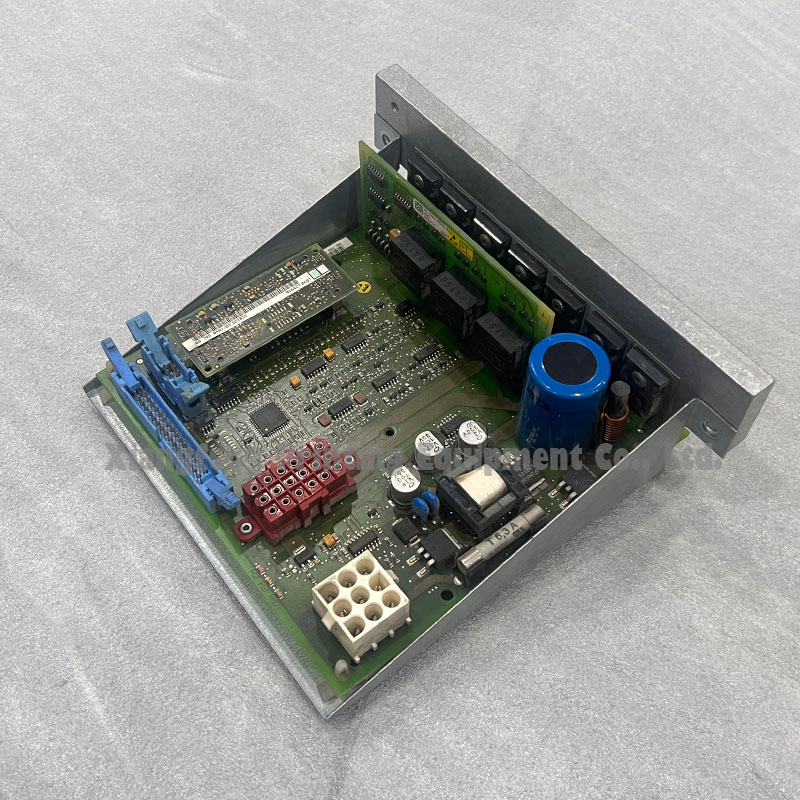

Printing machine circuit boards are critical components in industrial and commercial printing systems. They control motors, sensors, and other electronic components, ensuring accurate operation and high-quality output. Despite careful design and manufacturing, these boards can experience faults over time. Understanding common issues, preventive maintenance, and systematic troubleshooting is essential for reliable machine operation.

Common Operational Issues

Several types of problems can affect printing machine circuit boards. Power supply irregularities can cause intermittent operation or complete shutdowns. Components may fail due to heat, vibration, or dust, which can degrade solder joints, connectors, or board traces. Signal interference can lead to unexpected errors in sensor readings or motor control, affecting print quality. Boards with multiple layers are generally more resilient, but proper installation and environmental protection are equally important.

Maintenance Practices

Preventive maintenance plays a key role in reducing failures. Recommended practices include:

Troubleshooting Strategies

When a fault occurs, a systematic approach improves efficiency:

Following this methodical process helps minimize downtime and avoids unnecessary replacement of entire boards.

Integration Considerations

Modern printing machines often integrate multiple circuit boards for motor control, sensor feedback, and communication. Boards must be installed securely with proper grounding and signal shielding. Understanding the interaction between boards helps technicians diagnose cascading failures and optimize maintenance schedules.

Maintaining and troubleshooting printing machine circuit boards requires a combination of preventive care, careful observation, and structured diagnostics. A consistent approach ensures reliable operation, repair costs, and prolongs equipment lifespan.

Frequently Asked Questions

Q1: What are common faults in printing machine circuit boards?

A1: Frequent issues include loose connectors, solder joint deterioration, component overheating, and signal interference.

Q2: How often should preventive maintenance be performed?

A2: Maintenance schedules vary by machine usage, but visual inspection and cleaning every few months are generally recommended.

Q3: What tools are essential for troubleshooting?

A3: Common tools include multimeters, oscilloscopes, anti-static brushes, compressed air, and diagnostic software if available.

Q4: Can a board always be repaired?

A4: Many faults can be repaired by replacing specific components, but severe damage may require full board replacement.

Q5: How can integration of multiple boards affect troubleshooting?

A5: Interconnected boards can produce cascading faults. Isolating modules and understanding board interactions helps pinpoint the source of problems.

Contact Us